"Best Robot MIG Weld Practices

and Weld Process Controls

for gage to any thickness parts

"

Ed's

robot process control package which is item 2, was developed

for all carbon steels, low

alloy steels,

stainless,nickel steels and aluminum robot applications welding 20 gage to any thickness. The following is a brief description.

[2a]

The Training

CD: "Robot

MIG Weld Best Practices

and Process Controls"

[2b]

The

Book: "Manual

and Robot MIG Welding Process Controls"

[2c]

The DVD film: "Manual

MIG Process Control Made Simple"

Total

Cost for items 2a/b/c $395 plus shipping.

Order

this Welding Training Program

[Item 2a]

The Training Power Point CD:

"Robot

MIG Weld Best Practices & Process Controls. "Robot

MIG Weld Best Practices & Process Controls.

Irrespective of the robot application, this program provides

every

possible

optimum robot MIG weld requirement for

Short Circuit,

Globular, Spray and Pulsed welds.

THIS

UNIQUE, ANIMATED CD POWER POINT TRAINING PROGRAM REQUIRES

EIGHT HOURS CLASSROOM.

At one time, Ed was the Weld Manager for the North American

ABB Robotics Division. He was the first person in North America to establish Robot

Weld Process Control Training. During his 40 plus years as a weld process control

expert, Ed has assisted hundreds of companies in 13 countries in attaining robot

MIG, TIG and flux cored weld quality and productivity optimization. In the last

two decades, Ed has resolved numerous Motorman, Fanuc, OTC, Cloos, Panasonic

and ABB robot weld quality and productivity issues.

Robot Weld Quality - Productivity - Rework parts < 4 mm.

When

robot welding thin gage applications avoiding weld burn,

attaining consistent weld fusion

and minimizing distortion are important

to decreasing weld rework. For

thin gage welds, you can utilize 4 common weld transfer modes, short circuit,

globular, low spray data or pulsed. The issue many weld decision makers have,

is which is the optimum weld transfer mode and which are the optimum parameters

and weld consumables for those carbon steels and stainless gage welds. Instantly

select the correct robot weld data for any thin application. The easy to remember

data was developed by Ed to attain optimum weld quality with the highest possible

robot weld productivity.

Robot Weld Quality - Productivity - Robot Weld Quality - Productivity -

Rework on

parts > 4 mm.

Robot spray transfer and pulsed transfer welds on parts > 4 mm

to any thickness requires unique weld fusion and weld deposition

considerations. Ed

established the robot weld data for the world's largest trucks manufactured by

Caterpillar and set optimum robot data for the world's biggest selling truck frames

the Ford F150.

Ed has set robot welds on ships, boiler walls, trains, pipe lines, oil rigs, farm

/ construction equipment etc. and established optimum robot welds with most major

auto and truck part suppliers in twelve countries.

ROOT

CAUSES OF ROBOT DOWN TIME AND THE REQUIREMENTS FOR CONSISTENT OPTIMUM WELD PRODUCTION. ROOT

CAUSES OF ROBOT DOWN TIME AND THE REQUIREMENTS FOR CONSISTENT OPTIMUM WELD PRODUCTION.

The robot weld production - cost data that's presented in this program is extremely

beneficial as few robots achieve

their true daily weld production potential. Being

aware of the factors that influence your robot down time and weld production efficiency

potential and providing instant solutions to the many daily robot weld problems,

will have a dramatic impact on your weld quality and production costs.

Once you present this program, typically you can anticipate a 20 to 50% increase

in your daily robot weld productivity.

Process

Control training provides the ability to provide resolutions to weld issues. With

a few hours exposure to this animated CD program, your employees will have the

ability to provide instant solutions to things like:

[]

Robots and Lack of Weld Fusion.

[] Robots and LAvoiding Weld Burn Through.

[]

Robots and Weld Start Issues.

[] Robots and Optimizing Weld Tie Ins.

[]

Robots and Avoiding Wire Burn backs.

[] Robots and Minimizing Contact Tip Issues.

[] Robots and Weld Crater Issues.

[] Robots and

Weld Arc Start Instability.

[] Robots and Inconsistent Welds.

[] Robots

and Poor Weld Profiles.

[] Robots and Weld Spatter.

[]

Robots and Weld Porosity.

[] Robots and Weld Undercut.

[] Robots and The

unique requirements for attaining high deposition and high speed welds.

[]

Robots and The unique requirements for multi-pass welds.

[] Robots and Solutions

to Variable Gaps.

[] Robots and Process solutions to Part Dimension Inconsistency.

Reduce liability concerns. Minimize weld rework. Optimize weld productivity:

|

Many

companies will purchase two robots to produce weld production that could be attained

from one robot. Most companies are not aware of the real weld deposition rates

per application and the robot speeds that could be attained and few companies will establish the process

controls necessary to ensure consistent daily weld productivity with minimal robot

down time. This training provides your employees with the process knowledge and the

confidence they need to daily attain maximum weld productivity without robot down

time.

INSTANT

ROBOT MIG INSTANT

ROBOT MIG

WELDING BENEFITS:

When

all your weld decision makers know how to fine tune and set optimum robot MIG

weld data, the weld quality / productivity results will be both immediate and

dramatic.

No more weld trials to find optimum weld data, equipment

or consumables. No more time wasting playing around

with weld controls. Imagine the benefits of having employees with the ability

to instantly apply optimum process data that will ensure minimum downtime, minimum

rejects and minimum weld rework. When those robot weld problems occur, you

can call a team meeting or watch your trained workers instantly react with the

correct weld process resolutions to the weld issues.

Bring

all your weld decision makers to a training room. Place this CD in Bring

all your weld decision makers to a training room. Place this CD in

a laptop.

Project the program to the screen. In eight hours everyone has the necessary robot

MIG data to establish Best Weld Practices and implement Weld Process Controls.

The results are immediate.

[]

No more personnel playing around with the robot MIG weld controls.

[] No more

exasperating meetings discussing weld issues that never seem to get resolved.

[]

A dramatic reduction in robot down time.

[] Less concerns for product liability

weld issues.

[] Be aware of the real world part and weld gap tolerances for

all robot MIG welds.

[] When you have personnel using unique weld data and

techniques that are focussed on attaining consistent weld fusion and minimum weld

quality issues, the results are minimum

weld rejects and weld rework.

[]

With every weld you will ensure maximum weld deposition rates and the fastest

possible robot weld speeds.

[] Reduce the influence of sales and vendor advice

and provide

logical justification for MIG equipment and consumables.[] Your weld personnel

will have the resources to establish

highly cost effective, uniform Best Weld Practice for any plant and provide highly

effective Weld Process Controls for each robot cell.

Think

of the benefits of working in a manufacturing weld shop environment in which best

practices without sales bias and optimum robot weld process controls are established.

Your product liability concerns are reduced, and all the weld decision makers

take a uniform, professional, practical approach to the daily attainment of optimum,

robot weld quality and productivity.

Note:

As this CD program simplifies process controls, and presents the answers to the

majority of questions that could be asked, the person presenting the program needs

no weld process control expertise.

[Item 2b]

The Training Book. [Item 2b]

The Training Book.

"Manual

/ Robot MIG Welding Process Controls"

Written

by Ed Craig. (170

pages).

For

more Information, click here.

This

is a self teaching manual and Robot MIG Weld Process Control Training book. This

book presents Ed's unique, process control

Clock Method which provides a simple, highly effective approach to the selection

of optimum MIG parameters for any robot carbon steels, alloy steels and stainless

applications. This

book is an essential tool for MIG weld quality / productivity optimization and

a great resource for those participating in this training program.

[Item 2c]

The Training DVD film. [Item 2c]

The Training DVD film.

"Manual

MIG Process Controls Made Simple".

Produced

by Ed Craig. (Runs 60 minutes).

Remember

"a picture is worth a 1000 words. This DVD is a great visual tool in the

presentation of the simplification of optimum, CV MIG parameter selection using Ed's Weld Clock Method.

This

unique MIG training DVD has been purchased by hundreds of companies in 14 different

countries. Companies such as GM, Caterpillar, Case, Ford, Volvo, Tower Automotive,

Magna, Dana, ABB, Babcock, Boeing, Delphi, TRW, Monroe, Johnson Controls, Textron,

Genesis, General Dynamics, General Electric and numerous others.

Ed

took over 3000 hours to develop

this unique,

Robot Process Control Training Program.

Item

2a-b-c.

Total cost $395 .

To order item 2

Click here

E-mail:

From Ryan at Dana Corporation USA:

Ed,

I wanted to send update about that E-Town plant that you visited a few years ago:

As you know on your first visit to this plant, our robot lines were producing

less than 40 truck Ford F-150 frames per-hour and

the majority required extensive weld rework. Thanks to your robot weld process

control / best weld practices training program the results from our employees are today

staggering. Yesterday this plant hit very close to a record of 76

frames jobs per hour. We daily attain our

average goal of one frame per-minute. We had two recent weld audits. One weld

audit had a total of two failures, and the 2nd weld audit was the first 100% pass

weld audit in the history of the F-150 line. Ed,

I wanted to send update about that E-Town plant that you visited a few years ago:

As you know on your first visit to this plant, our robot lines were producing

less than 40 truck Ford F-150 frames per-hour and

the majority required extensive weld rework. Thanks to your robot weld process

control / best weld practices training program the results from our employees are today

staggering. Yesterday this plant hit very close to a record of 76

frames jobs per hour. We daily attain our

average goal of one frame per-minute. We had two recent weld audits. One weld

audit had a total of two failures, and the 2nd weld audit was the first 100% pass

weld audit in the history of the F-150 line.

Many

thanks Ryan Good. Dana

Corporation.

2007: Update from Ryan. Hey Ed:

Just thought I would drop you a line and let

you know that in the beginning of April we will be working on switching over the

5th Dana plant to ther process recommendations of an 0.040 wire and the traditional

spray mode, instead of the 0.052 (1.4mm) wire and using the Rapid Arc (Lincoln's pulse program).

Thanks again RG.

E-mail

From: Tom Plummer. Tenneco USA:

Good

afternoon Ed.

Tenneco

has plants all over the world. We have been very enlightened by your " Robot

MIG Weld Process Control" training materials " We are slowly implementing

your process control and best practice concepts to the shop floors.

E-mail.

From Jose Ignacio Moreno. Johnson Controlls. Spain.

Ed.

I work as manufacturing engineer in Johnson Controls Alagon (Spain). We mainly

build car seat structures. And we have some robot welding cells. Last week I received

your robot process control material, which I've been reviewing. I find it really

interesting and practical.Your approach to weld process control is unique and

it certainly works. It seems you have been in our company, as most of the robot

MIG weld issues you address are part of our every day work. Thank you JM.

E-mail

From Marcus di Sabella Magnaflow.

CA.

Ed, I just received your robot process

control materials and within five minutes of skimming I found many flaws in our

weld techniques and process data. These materials will be very helpful to our

organization! Thanks for your expertise and prompt service!

Process

Engineer.

Car Sound Exhaust System, Inc / Magnaflow Performance Exhaust.

Rancho

Santa Margarita, CA.

E-Mail:

Ed

your

story of reading weld literature and finding it was not as it seems inspired me

to do the same. Over the last three years all I have done and continue to do is

read from a variety of welding resources. So this past week I have focused my

study on the "hands-on" practical aspect. Its amazing what you learn

from having your nose in the arc rather than observing from out side a fence.

Tonight thanks to your books and training resources I was able to

figure out how you achieved robot speeds of 70 to 100 inch/min in the spray mode.

As per your instructions I found a gas diffuser that was shorter than our common

ones. I then took your advice from your WELD MANAGEMENT AND ENGINEERS book and

cut about a 6 mm off the end of a tip. With having the tip recessed in to nozzle

allowed for a longer stick out dropping the amperage but still within the spray

range. The longer wire stick out permitted me to run higher WFS (deposition rate)

without the extra amperage that would cause unwanted weld defects like weld burn

through. The spatter was minimal and easy to remove. Also the recessed tip and

diffuser were spotless. A

Ed

Thanks for your contribution to my weld education.

Matt Finn. USA.

This

program is applicable to all types

of robots and weld equipment.

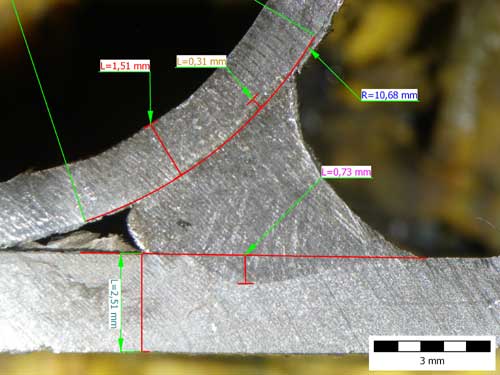

The

Weld Issue. The macro of the weld on the right indicates lack of MIG weld

fusion when robot welding thin gage 1.5 to 2.5 mm carbon steel parts. The

Weld Issue. The macro of the weld on the right indicates lack of MIG weld

fusion when robot welding thin gage 1.5 to 2.5 mm carbon steel parts.

The

robot weld data used was a typical short circuit setting. The 0.035

(1mm) wire feed was set at 280 inch/min, (7 m/min). 170 amps. 18 volts. The weld

travel rate was 20 inch/min, (0.5m/min).

The weld gas was argon - 15% CO2.

As

an experienced weld decision maker you know you can improve the weld fusion by

changing the 0.035 wire weld parameters to the following....

[a]

Set the highest attainable short circuit weld settings.

Provide

Wire Feed____ Amps____ Voltage ____ Travel Rate____

[b]

Set a higher energy controlled globular transfer weld settings.

Provide

Wire Feed____Amps____Voltage ____ Travel Rate____

[c]

Set the start point of spray transfer parameters and change the gun angle.

Provide

Wire Feed____Amps____Voltage ____ Travel Rate____

[d]

Change the weld wire to 0.045 (1.2mm) and set suitable pulsed

parameters that

will not burn through.

Provide

Wire Feed____ Amps____Voltage ____ Travel Rate____

The

above required weld settings tell you the importance of process data awareness.

This resource will give you and your organization, the ability to make "playing

around" with weld data an obsolete function in your organization.

Don't

play around with your robot weld controls and settings,

provide

instant solutions and avoid weld defects.

Ed

set the robot welds for Volvo Cabs, Corvette, Harley and Ford 150 truck frames.

[]

Robots and Weld Rework: It's typical in many plants to find excess weld rework

required for those robot welds. This program identifies the root causes of weld

rework and deals with all the major issues that impact weld quality and rework.

[]

Robots and Weld Defect Prevention. All the common weld defects are covered

and the robot process control data is provided to ensure your defects are minimized

and weld rework in minimum.

[]

Robots Weld Deposition Rates and High Speed Welds: This training shows you how

to always attain the maximum weld deposition rates and provides the data necessary

to attain the highest possible

robot weld speeds.

[] Robots and Down

Time. High robot speeds and production efficiency become meaningless when the

robot spends 30 minutes to 120 minutes minutes per-shift in down time. For every

issue that causes down time there is a resolution presented in this program

[]

Robots and MIG Equipment: The training cuts

through the sales bias of weld equipment and makes you aware of why Inverters

and Pulsed MIG equipment can enhance weld quality on some applications and may

have dramatic negative weld quality impact on other applications.

[]

Robots and

Weld Process Calibration: Few global robots have received correct robot / power

source calibration. In attaining consistent daily weld quality and production

performance the contractual requirements of calibration are provided and need

to be understood by engineers and managers.

Ed

set this robot to weld a 40 diam pipe.

1980s

to early nineties:

[1] Ed was the first

person in North America to set a robot to weld all position flux cored weld for

a 40 inch pipe line.

[2] Ed was also the

first in the world to set ASME qualified robot pulsed MIG

welds for the difficult task of welding boiler pipe to headers. Customer was ABB

Combustion Eng.

[3] Ed was the first person

in the world to set on site, robot Inconel / stainless pulsed MIG clad welds inside

a water wall boiler.

[4] Ed was the first

person in the USA to set a "multi robot line. 4 robots" to successfully

MIG weld a large aluminum part. (golf car frame)

In

the early nineteen nineties,

Ed established

the multi-robot pulsed MIG data, for these aluminum golf cart

frames.

For the best in robot weld quality consider TIP TIG.

Note:

As Ed has a reputation for weld process control simplification.

The weld decision

maker who presents this presentation needs

no robot weld process control expertise.

Visit Ed's MIG Welding and Flux Cored Training Materials.

|